Why is membrane switch a preferred choice in automotive dashboards?

Wiki Article

Discovering the Uses of Membrane Change in Various Industries

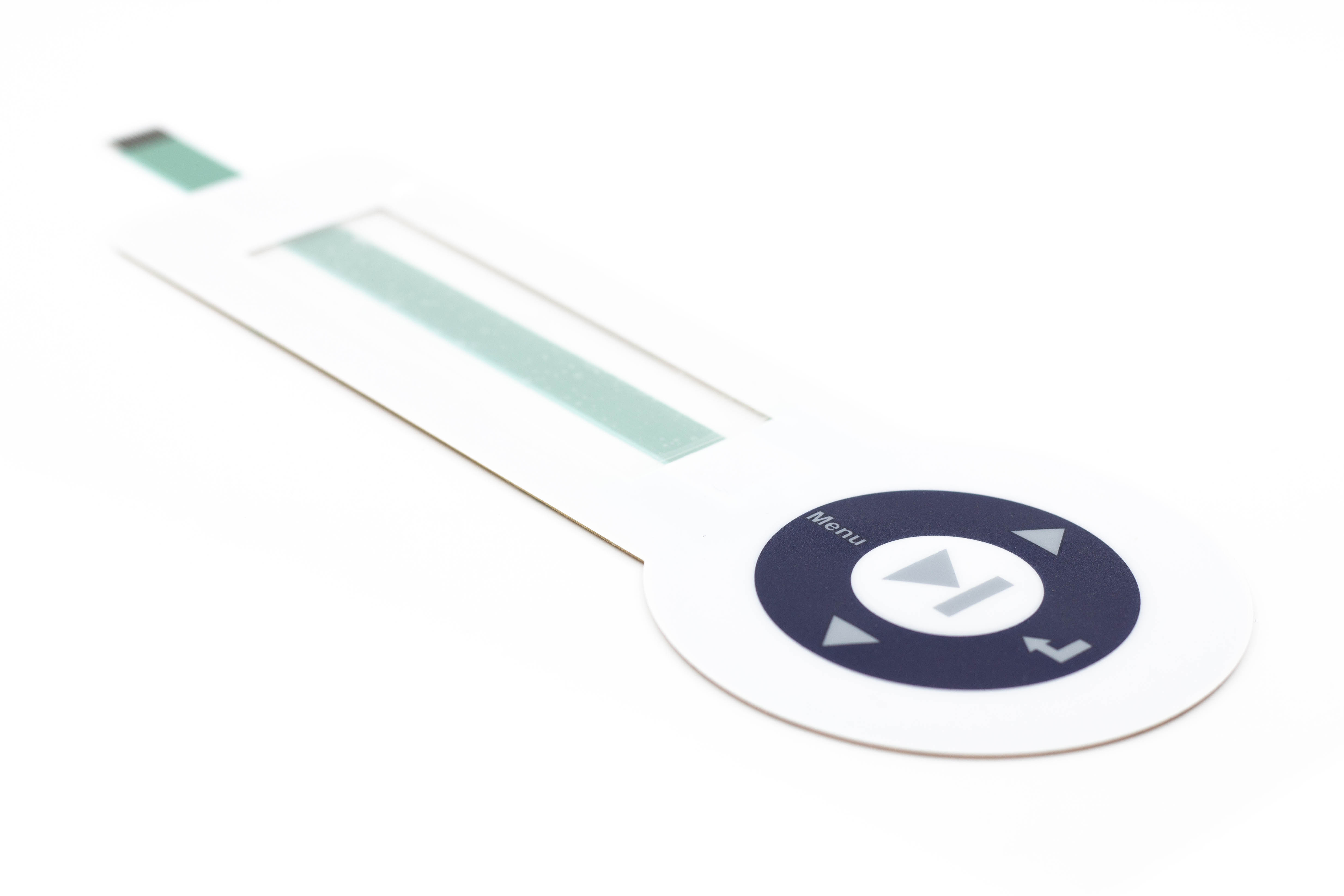

Membrane layer switches are important components across numerous industries, consisting of customer electronic devices and automobile markets. Their long lasting and light-weight nature permits effective use in small tools. Furthermore, these switches offer resistance to environmental aspects, boosting their longevity. As industries develop, the demand for adjustable options expands. This elevates vital questions about the future applications and advancements of membrane layer button technology. What new possibilities lie ahead for this versatile component?Membrane Switches in Customer Electronic Devices

Membrane layer switches play a necessary duty in customer electronic devices, using an efficient interface for different devices. These switches are designed to be light-weight and thin, making them optimal for contemporary gadgets where room goes to a premium. Their flexibility enables integration right into diverse products, varying from family home appliances to handheld devices. The responsive comments offered by membrane switches over improves user communication, making certain a smooth experience.Moreover, membrane buttons are resistant to moisture and dust, which is important for keeping performance in everyday atmospheres. They can be customized with numerous graphics and shades, enabling producers to straighten with branding demands. Additionally, the cost-effectiveness of membrane layer switch modern technology makes it a preferred selection for mass-produced electronics. As customer demand for streamlined, user-friendly tools continues to expand, the importance of membrane layer switches in supplying dependable, reliable interfaces comes to be increasingly noticeable, solidifying their location in the electronic devices industry.Applications in the Automotive Market

In the auto market, membrane layer buttons are utilized to enhance both functionality and aesthetic appeal within lorries. These switches are frequently incorporated into dashboards, control panels, and infomercial systems, providing a sleek and modern-day interface for passengers and chauffeurs. Their style permits for smooth integration with various materials, which adds to the general aesthetic allure of the vehicle's interior.Furthermore, membrane switches are valued for their toughness and resistance to ecological variables such as moisture, temperature, and dust variations. This makes them optimal for applications in automotive setups, where dependability is essential. Furthermore, they can be tailored with different graphics and designs, enabling producers to create unique branding elements and customer experiences.As vehicle innovation remains to advance, the need for ingenious control services will likely drive even more developments in membrane layer button applications, ensuring they remain a crucial part in contemporary car layout.The Function of Membrane Switches Over in Health Care

Commonly neglected, the duty of membrane buttons in healthcare is crucial for making sure the efficient operation of clinical devices and tools. These switches work as user interfaces for a selection of applications, including diagnostic equipments, client surveillance systems, and surgical tools. Their style permits for simple cleansing and sterilization, which is important in keeping hygiene in clinical environments.Membrane buttons are also recognized for their toughness and resistance to wear, making them excellent for devices that withstand frequent use. Their tactile feedback gives users with a trustworthy experience, boosting use for medical care experts. Furthermore, membrane switches can be personalized with various graphics and designs, guaranteeing that they fulfill certain needs of different medical applications. In general, the combination of membrane switches in health care innovation not just enhances performance however additionally adds to person safety and security and functional performance within medical centers.Aerospace Innovations With Membrane Layer Change Innovation

Industrial Automation and Membrane Layer Switch Over Solutions

Membrane switch modern technology is increasingly discovering applications in commercial automation, where reliability and effectiveness are vital. These buttons work as important parts in numerous automated systems, promoting user interactions in atmospheres that demand toughness and durability. Their design permits a seamless combination with control board and tools, making certain convenience of use for operators.In industrial settings, membrane switches can withstand severe conditions, including exposure to dust, moisture, and extreme temperature levels. This resilience makes them ideal for applications in manufacturing, logistics, and process control. Additionally, their customizable attributes enable firms to develop customized options that satisfy certain operational needs.The tactile feedback provided by membrane layer switches over improves individual experience, decreasing the chance of mistakes throughout operation - membrane switch. As markets proceed to progress towards better automation, the role of membrane button innovation is expected to broaden, driving effectiveness and boosting workflow in intricate industrial atmospheres

Often Asked Questions

What Products Are Commonly Made Use Of in Membrane Layer Switch Construction?

The materials frequently used in membrane layer switch construction include polyester, polycarbonate, glue layers, printed graphics, and conductive inks. These parts guarantee versatility, durability, and responsiveness, making them appropriate for different digital applications in varied sectors.

Exactly How Do Membrane Layer Switches Over Contrast to Traditional Switches in Resilience?

Membrane changes commonly offer exceptional sturdiness contrasted to typical buttons, as they are much less Read Full Article vulnerable to mechanical wear and tear. Their sealed design safeguards against dust and moisture, improving durability in different applications.Can Membrane Layer Switches Over Be Personalized for Details Applications?

Membrane layer buttons can without a doubt be personalized for specific applications. Their style versatility enables for tailored shapes, functionalities, graphics, and dimensions, making them ideal for diverse environments and enhancing customer communication across numerous digital gadgets and equipment.What Are the Ecological Considerations for Membrane Switch Over Disposal?

The environmental considerations for membrane layer switch disposal consist of prospective hazards from products used, reusing chances, and adherence to regulations. membrane switch. Correct disposal techniques are read this vital to decrease environmental impact and advertise sustainability within manufacturing procedures

How Do Membrane Layer Switches Effect Customer Experience in Tools?

Membrane layer switches considerably enhance individual experience via tactile responses, sturdiness, and layout flexibility. Their smooth integration into tools fosters user-friendly communications, while their visual appeal can raise item presentation, eventually adding to user fulfillment and involvement. The tactile comments supplied by membrane layer switches enhances individual communication, ensuring a seamless experience.Moreover, membrane switches are resistant to wetness and dirt, which is important for maintaining functionality in daily atmospheres. In enhancement, membrane layer buttons can be customized with various graphics and layouts, guaranteeing that they satisfy certain needs of various clinical applications. Membrane layer buttons are also resistant to moisture and impurities, ensuring sturdiness and long life in numerous cabin and cabin applications. Membrane layer button innovation is progressively discovering applications in industrial automation, where dependability and effectiveness are vital. Membrane switches usually provide exceptional resilience compared to traditional buttons, as they are much less susceptible to mechanical wear and tear.Report this wiki page